Viscosity Index

Viscosity refers to a fluid’s resistance to flow. A higher viscosity indicates a thicker fluid, resulting in slower flow. The Viscosity changes with temperature to provide effective protection and proper operation under various conditions. The viscosity index (VI) is a dimensionless numerical measure that reflects the extent to which a lubricant’s viscosity changes with temperature variation. It enables a more effective comparison of the viscosity behavior of different oils as temperatures vary. A higher VI indicates that the lubricant consistently retains its viscosity over a wide range of temperatures, which is advantageous for various uses, such as in engines or hydraulic systems.

History

Since machines need a specific viscosity, and temperature is the primary factor affecting the changes in the oil viscosity, it’s crucial to understand how viscosity changes with temperature. The viscosity index was created to address this need (ASTM D2270) by Dean and Davis in 1929. At that time, multi-grade oils and synthetic oils were not available. Two reference points were created for the VI scale. Oils exhibiting minimal viscosity change with temperature variations, refined from Pennsylvania crudes and consisting of paraffinic oil, considered as high viscosity index (HVI) occupied the upper end of the scale, with a VI of 100 signifying the best viscosity index.

Conversely, oils that undergo significant viscosity changes, refined from Texas Gulf crudes and consisting of naphthenic oil, considered as low viscosity index (LVI) oils, represented the lower end, assigned a VI of 0, marking the most unfavorable VI. These VI values pertained to mineral oils. Lubricating oils were then assessed against these references. Oils resembling paraffinic oils were given a VI of 100, while those similar to naphthenic oils received a VI of 0. A VI of roughly 50 would be given to those in between. Later developments of new base oil types and specific additives enabled the enhancement of VI values beyond 100.

Curious about how heat influences fluid behavior?

Discover the science behind Viscous Heating: Mechanisms, Effects, and Applications and explore its impact on real‑world processes.

In the earlier VI systems, viscosity measurements were conducted at 100 °F and 210 °F, which correspond to 37.78 °C and 98.89 °C. The Fahrenheit scale is still commonly used in regions such as the Anglo-American area. Currently, measurements at 40 °C and 100 °C are more common. Initially, viscosity was measured in Saybolt Universal Seconds (SUS), but today, kinematic viscosity is measured in mm²/s for VI calculations.

Understanding The Viscosity-Temperature Behavior in Oils

In contrast to water, which maintains a consistent flow behavior across a broad temperature range, oil experiences significant changes in viscosity with temperature variations. Additional factors such as oxidation, contamination, and operational pressure also influence viscosity. Moreover, the relationship between viscosity and temperature is nonlinear, following a double logarithmic pattern.

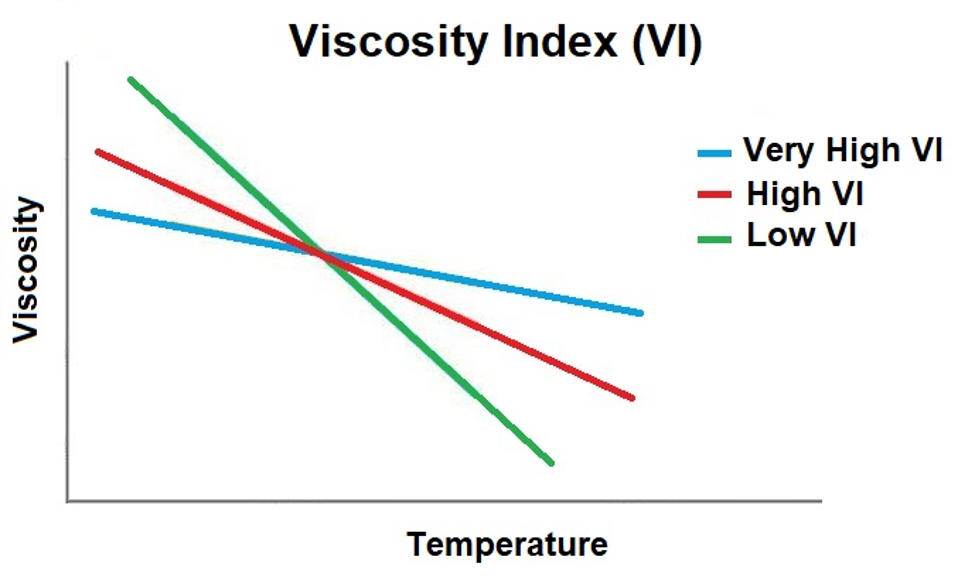

A low Viscosity Index (VI) indicates a substantial change in viscosity with temperature fluctuations. Oils with a low VI tend to be very thick at lower temperatures and relatively thin at higher temperatures. Conversely, a high VI suggests minimal changes in viscosity across a wide temperature spectrum (see Figure 1).

figure 1

When selecting oil for a specific application, such as for lubrication in an internal combustion engine, it is essential to take into account the temperature-dependent viscosity variations, as these differ among oil types. Oils that display the same kinematic viscosity at 40 °C may exhibit significantly different characteristics at 100 °C. To achieve the desired viscosity properties at various temperatures, viscosity index improvers, also referred to as viscosity modifiers, are incorporated into the base oil. The highest achievable VI is influenced by the type of base oil used, as well as the kind and concentration of VI improvers added to the oil. The VI values for common oil types can range from -60 to over 400. The proportion of viscosity modifiers typically falls between 5% and 20%. The viscosity indexes of various fluids are summarized in Table 1.

Table 1: Viscosity index of different fluids

| Viscosity index | Oil/fluid types |

|---|---|

| 95 – 105 | Mineral oil |

| 140 – 200 | Multi-grade oil |

| 135 – 160 | PAO oil |

| 140-190 | Ester |

| 195 – 210 | Vegetable oil |

| 200 – 220 | Glycol |

| 205 – 400 | Silicone oil |

Viscosity Index Modifiers and How They Stabilize Lubricants Across Temperatures

Final formulated lubricants incorporate a range of additives. Among the most critical categories are viscosity index improvers (VII) or viscosity modifiers. These additives primarily consist of oil-soluble polymers or copolymers.

Viscosity Index Improvers (VIIs) play their crucial role in enhancing the performance of lubricants by adjusting their molecular structure in response to temperature changes. As temperatures rise, these molecules expand, significantly increasing the lubricant’s resistance to flow. This expansion prevents the lubricant from becoming too thin under high heat, maintaining its effectiveness. Conversely, when temperatures drop, the VIIs contract, allowing the lubricant to remain sufficiently fluid for smooth circulation within the engine or machinery. This remarkable adaptability not only ensures optimal performance across a wide temperature range but also helps to retain the essential protective properties of the lubricant, safeguarding vital components from wear and tear.

While viscosity index improving additives play a crucial role in enhancing the performance of lubricating oils, they are not without their drawbacks. One significant disadvantage is their susceptibility to aging, which occurs as a result of continuous mechanical shearing during operation. This shearing action disrupts the molecular chains within the additives, potentially leading to a gradual decline in their effectiveness. As the additives age, they lose their ability to maintain the thickening function of the oil, especially under elevated temperatures. While choosing polymers with a higher molecular weight could enhance thickening properties, they exhibit less resistance to mechanical shearing. Alternatively, polymers with a lower molecular weight are more resistant to shearing but do not effectively increase viscosity at higher temperatures. Therefore, they must be utilized in larger amounts.

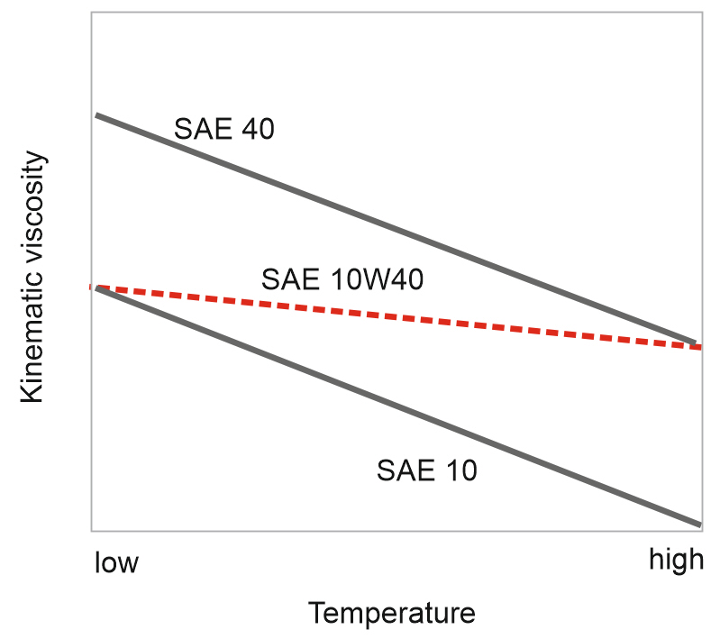

Ultimately, the absence of viscosity index improvers would make it exceedingly challenging to formulate modern multi-grade lubricating oils. These improvers are essential for maintaining consistent viscosity across a range of operating temperatures, thereby ensuring optimal performance and protection of mechanical components in various applications. Figure 2 illustrates how viscosity index improvers affect the temperature-dependent viscosity variations of the oil.

figure 2

The practical example in this figure highlights two mono-grade oils designed for use in road vehicle engines. SAE 10 has a lower viscosity at low temperatures compared to SAE 40. Generally speaking, the former is suited for cold conditions: it is termed the “winter” oil. SAE 40, on the other hand, is intended for warmer conditions, known as the “summer” oil. By incorporating viscosity index improvers (along with other additives) into SAE 10, a multi-grade oil can be created that combines both characteristics: the SAE 10W-40. This multi-grade oil possesses attributes of both: the excellent pumpability of SAE 10 at low temperatures and a denser, more stable oil film at the higher temperatures of SAE 40. Utilizing a multi-grade oil eliminates the necessity of changing engine oil with the changing seasons.

VI Modifiers: What They Are and Where They Are Used

Common materials used as VI modifiers include olefin copolymers (OCP), polyalkyl methacrylates (PAMA), polyisobutylenes (PIB), styrene block polymers, methyl methacrylate (MMA), polybutadiene rubber (PBR), cis-polyisoprene (a type of synthetic rubber), polyvinyl palmitate, polyvinyl caprylate, and copolymers of vinyl palmitate with vinyl acetate. These substances are mostly used in multi-grade engine oils, gear oils, and automatic transmission fluids. They are also used in power steering fluids, hydraulic fluids, and greases. These additives are crucial for vehicles, boats, and aircraft, particularly in managing temperature fluctuations during operation.

Viscosity Index Calculation

There are two standard methods to calculate the viscosity index: ASTM D22706 and ISO 29097. These methods are currently recognized for calculating the VI of petroleum products utilized in both civil and military sectors.

The viscosity index is crucial for both newly formulated oils and those that are already in use. For the latter category, it serves as a means to assess the deterioration of viscosity modifiers, which typically results in a reduced VI. It should be noted that the viscosity index applies solely to petroleum products exhibiting a kinematic viscosity above 2 mm²/s at a temperature of 100 °C.

Want to extend the life of your lubricants?

Learn how oxidation impacts oil performance and how to detect and prevent it in

Calculating the Viscosity Index Using ASTM D2270

Calculating the Viscosity Index using ASTM D2270 involves a series of precise measurements and calculations:

1. Measure Kinematic Viscosity at 40°C (KV40): The first step is to accurately measure the lubricant’s kinematic viscosity at a standard temperature of 40°C. This value is typically expressed in centistokes (cSt).

2. Measure Kinematic Viscosity at 100°C (KV100): Next, the kinematic viscosity is measured at a higher temperature, 100°C. This measurement is vital as it reveals how the oil’s flow characteristics respond to increased heat.

3. Determine Reference Oil Viscosities (L and H): Using the measured KV100 value, we identify two hypothetical reference oils:

L: This represents the viscosity at 40°C of a reference oil that has the same KV100 as your lubricant but possesses a Viscosity Index of 0.

H: This represents the viscosity at 40°C of a reference oil that also shares the same KV100 as your lubricant but has a Viscosity Index of 100.

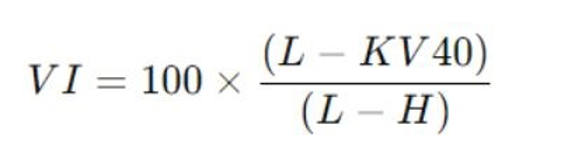

4. Apply the VI Calculation Formula: Once L and H are determined, the Viscosity Index is calculated using a specific formula. For lubricants where the KV100 is less than or equal to 70 cSt, the formula is:

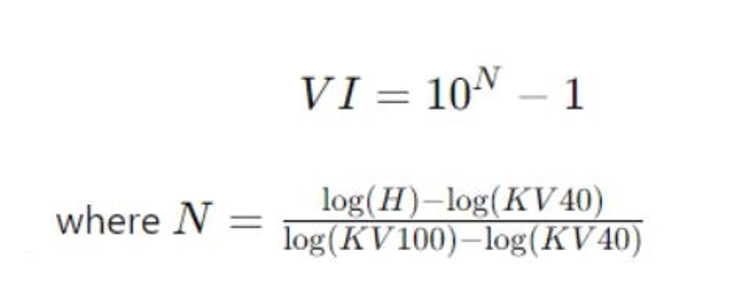

For lubricants where the KV100 is greater than 70 cSt, the formula is:

Viscosity Index: Common Questions Answered

A high VI means the oil’s thickness changes very little with temperature shifts, ensuring stable performance in both hot and cold conditions.

It helps maintain optimal lubrication and reduces wear, preventing the oil from becoming too thin in heat or too thick in cold starts.

Yes. Manufacturers add special polymers called viscosity index improvers to enhance VI without altering the oil’s basic chemistry.

Not always. The right VI depends on the equipment, operating conditions, and balance with other performance properties.

Generally yes, synthetic oils tend to have a higher and more stable VI, offering better performance over a wider temperature range.

It’s usually listed on the product data sheet (PDS) or technical specifications provided by the manufacturer.

Yes. Heat, mechanical stress, and contamination can degrade VI improvers, causing the oil’s temperature stability to drop.

Indirectly, yes. Oils with the right VI reduce friction losses and improve the engine’s overall efficiency.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us

no comment