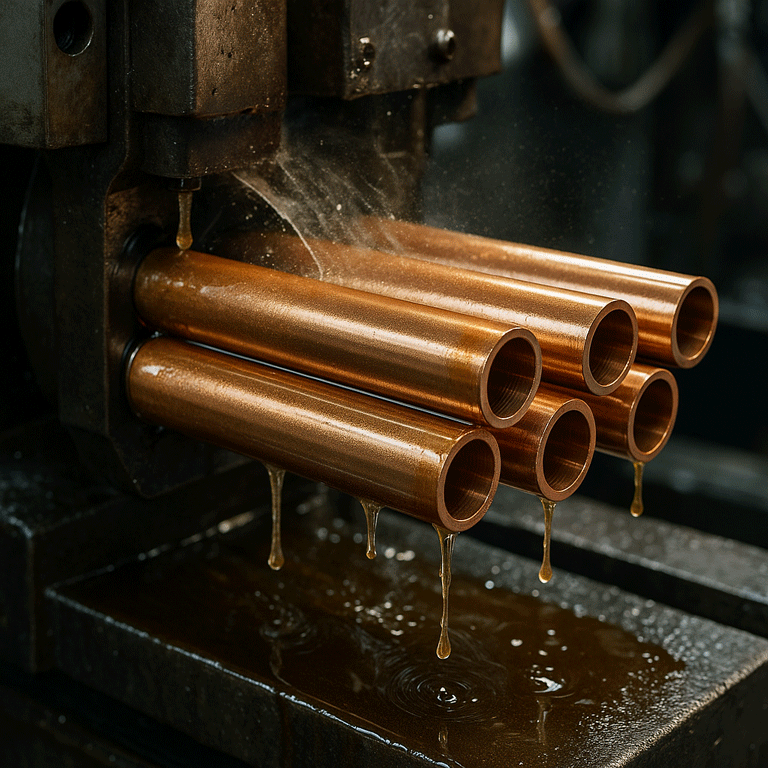

Evaporative Oil for Copper Tubes

Our best services and products are at your disposal. For more information or to place an order, just click the button below right now and take the first step!

Evaporative Oil for Copper Tubes

Share This Product:

Product Introduction

Evaporative Oil for Copper Tubes

Evaporative oil for copper tubes plays a vital role in cooling and lubricating systems, and choosing the right oil helps increase the lifespan and optimize the performance of the system.

Types of Evaporative Oil for Copper Tubes

Evaporative copper tube oils are specially formulated oils used for shaping copper tubes in cooling and lubricating systems. There are several types of evaporative oils for use in copper tubes, including:

Mineral Oils

Mineral oils are the most common type of evaporative oils and are derived from crude oil refining. They are affordable and have good lubrication properties. Types of mineral oils:

– Light Mineral Oils: Suitable for forming and drawing applications with low expansion stress.

– Heavy Mineral Oils: Suitable for forming and drawing applications with high expansion stress.

Synthetic Oils

Synthetic oils are produced in laboratories and, compared to mineral oils, have higher thermal and chemical stability. They are more expensive, but offer superior properties to mineral oils.

Vegetable Oils

Vegetable oils are derived from plant sources and are biodegradable. However, their lubrication properties may be inferior to mineral or synthetic oils, making them more suitable for environmentally sensitive applications.

Benefits of Using Evaporative Oil for Copper Tubes

Using the appropriate evaporative oil for copper tubes brings multiple benefits, generally leading to increased lifespan, efficiency, and system performance, while reducing maintenance costs. These benefits can be categorized as follows:

1. Improved System Performance:

– Reduced Friction and Wear:

Evaporative oil creates a thin lubricating layer between metal surfaces, significantly reducing friction between moving parts such as jaws and dies (if present). This minimizes wear and tear and increases parts’ lifespan, reducing product failure due to component damage.

– Prevention of Overheating:

Some evaporative oils not only lubricate but also act as coolants. By absorbing heat, they prevent copper tubes, wires, or related components from overheating. This is especially important in systems operating at high temperatures.

– Increased Efficiency:

By reducing friction and preventing overheating, overall system efficiency is significantly increased. Proper lubrication means less energy consumption and more optimized performance, resulting in fewer product failures during production.

2. System Protection:

– Prevention of Corrosion and Rust:

Evaporative oil forms a protective layer on the copper surface against moisture, oxygen, and other corrosive factors. This prevents corrosion and rusting of copper tubes and other components, maintaining long-term performance and quality.

– Prevention of Deposit Buildup:

Evaporative oil can help prevent the accumulation of contaminants, dust, and deposits within the system, supporting oil quality and proper system operation.

3. Reduced Maintenance Costs:

– Less Need for Repairs:

By reducing wear, corrosion, and buildup, the need for repairs and replacement parts is significantly lowered.

– Reduced Downtime:

With fewer repairs needed, system downtime for maintenance is minimized.

Choosing the right type of evaporative oil depends on various factors, such as the system type, operating temperature, and environmental conditions. Therefore, consulting with experts in this field is highly recommended before selecting an oil.

Characteristics of Evaporative Oil for Copper Tubes

The suitable evaporative oil for copper tubes should meet several general requirements, and choosing the right oil should be based on the specific needs of the cooling or lubricating system, the forming method, and the stress level on the workpiece surface. These characteristics include:

1. Physical Properties:

– Viscosity:

Viscosity is the oil’s resistance to flow. The oil’s viscosity should match the system’s operating temperature and conditions. Too low or too high viscosity can harm system performance. Proper viscosity ensures uniform distribution and effective lubrication.

– Pour Point:

The lowest temperature at which the oil still flows easily. At lower temperatures, oil can become thick and disrupt system function. Low pour point is essential for systems operating in cold environments.

– Flash Point:

The lowest temperature at which oil vapors can temporarily ignite. A high flash point improves system safety against fires.

– Initial Boiling Point (IBP):

The temperature at which the oil starts to boil and evaporate. A high boiling point is important to prevent excessive oil evaporation at operating temperatures.

– Density:

Represents the weight per unit volume. Appropriate density is required for efficient oil distribution within the system.

2. Chemical Properties:

– Thermal Stability:

The oil’s ability to withstand high temperatures without breaking down or altering its properties. High thermal stability prevents deposit formation and performance decline.

– Oxidation Stability:

The oil’s resistance to oxidation (reaction with oxygen). Oxidation can lead to sludge, acid, and deposits. High oxidation stability increases the oil’s lifespan.

– Compatibility with Metals:

The oil must be compatible with metals used in the system, such as copper and aluminum, and should not cause corrosion or rust. Lack of compatibility can damage systems and reduce their lifespan.

Product Features

- Provides a thin lubricating layer to reduce friction and wear between surfaces.

- Helps prevent overheating by absorbing heat during high-temperature operations.

- Forms a protective layer to prevent rust and oxidation on copper surfaces.

- Prevents the buildup of contaminants, sludge, and deposits within the system.

- Maintains appropriate viscosity for effective lubrication under various conditions.

- Resists breakdown and oxidation at high temperatures, ensuring long-term performance.

- Includes environmentally sensitive formulations like biodegradable vegetable oils.

To maintain the performance, quality, and lifespan of Evaporative Oil for Copper Tubes, it is essential to store it under optimal conditions. Below are scientifically supported guidelines for storing this type of oil:

1. Storage Environment

Store the oil in a dry and well-ventilated indoor area, away from direct sunlight, moisture, and extreme weather conditions. Avoid proximity to flames, heat sources, or any flammable materials to reduce fire risks.

2. Sealed Containers

Use airtight and corrosion-resistant containers designed for industrial oils. This prevents contamination by dust, water, or air. Inspect the containers periodically for signs of damage, leaks, or corrosion.

3. Temperature Range

Ideal storage temperature is between 10°C and 30°C. Exposure to temperatures outside this range may lead to changes in oil viscosity, flash point, and overall performance. Avoid freezing environments, as they could affect the oil’s flow characteristics.

4. Protection from Moisture and Oxidation

Minimize exposure to humidity to protect the oil from water contamination, which can degrade its quality and damage metal components. Store the oil in closed containers to limit exposure to oxygen, which can promote oxidation and lead to sludge formation.

5. Rotation and Shelf Life

Use the first-in, first-out (FIFO) method to ensure older stock is used first. Evaporative oil generally has a shelf life of 12 months under proper storage conditions. Inspect the oil periodically for any signs of degradation, such as changes in color, smell, or particles in suspension.

6. Labeling and Safety Compliance

Clearly label the containers with the oil type, manufacturing date, and expiration date to ensure proper usage and prevent mix-ups. Comply with safety and handling standards, including Material Safety Data Sheets (MSDS).

7. Avoid Contaminants

Ensure the storage area and equipment used for handling oil remain clean to prevent contamination by dirt, dust, or debris.

By adhering to these storage guidelines, industries can optimize the performance, efficiency, and lifespan of Evaporative Oil for Copper Tubes, ensuring consistent and reliable system operations.

Packaging

Evaporative oils for copper tubes are packaged and supplied in standard 208-liter barrels.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us