introduction

In diverse industrial sectors, lubricating oils serve as the lifeblood of machinery, acting as protectants, friction reducers, and rust inhibitors. They keep moving components operating efficiently while minimizing wear and corrosion. Yet, even the most advanced lubricants are susceptible to industrial oil degradation, driven mainly by temperature fluctuations and contamination. Left unchecked, these factors accelerate oil breakdown, compromise equipment longevity, and raise operational costs

This article takes a practical, engineering-focused approach to examine these damaging influences and outline proven methods to preserve lubricant quality, ensuring equipment reliability in the long term

The Impact of Temperature Variations on Lubricants

a) Low-Temperature Effects

Cold operating environments can hinder lubricant performance in several ways

Viscosity surge: At lower temperatures, oil thickens, restricting flow and reducing its load-bearing capacity

Stiffening in narrow passages: Heavy, sluggish oil struggles to circulate through bearings and channels

Phase separation or gelling: Extreme cold can cause base oil and additives to separate or partially solidify

Additive precipitation: Certain chemicals may fall out of solution, clogging lubrication lines

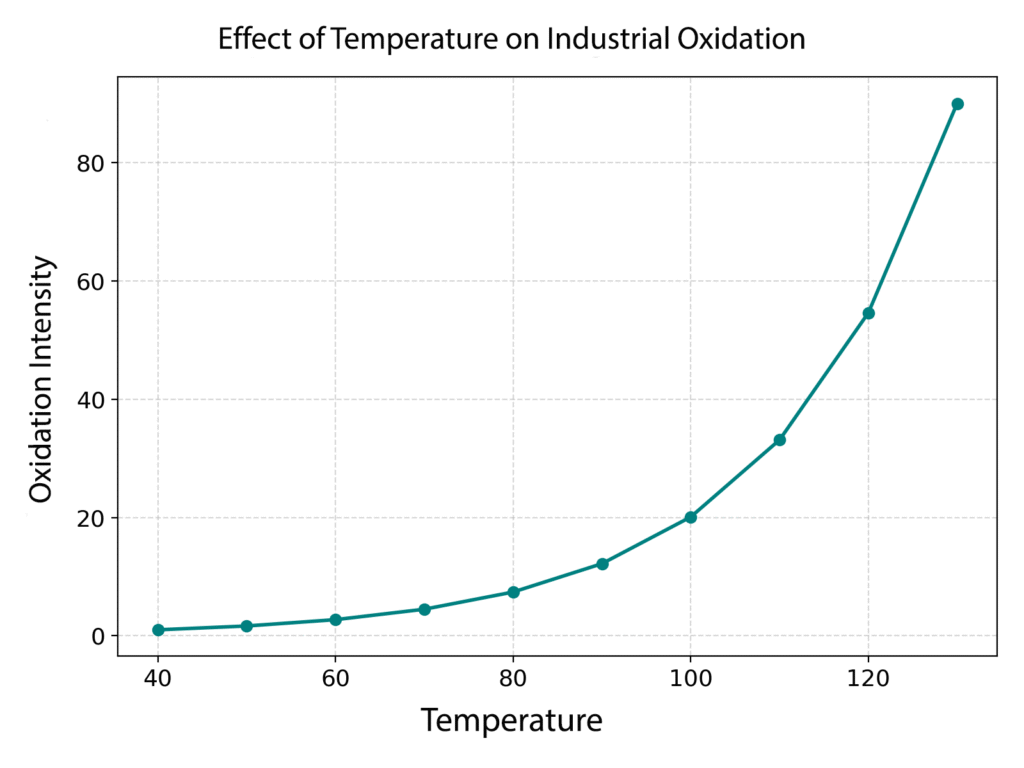

b) High-Temperature Effects

Excess heat is one of the strongest accelerants of industrial oil degradation

Rapid chemical breakdown: Following the Arrhenius equation, oxidation rates double with every 10°C rise

Accelerated oxidation: Leads to acidic byproducts, sludge formation, and filter blockages

Additive depletion: Anti-wear and anti-oxidant agents lose effectiveness under sustained heat stress

Volatilization: Lighter oil fractions evaporate, altering viscosity and chemical balance

Sludge-induced viscosity increase: Deposit buildup thickens oil, reducing lubricating ability

Temperature control practices

Maintain heat within recommended thermal ranges via Thermal Lubrication Charts

Install multi-point temperature sensors

Apply cooling systems and adequate ventilation in hot environments

Contamination Types and Their Role in Oil Degradation

a) Water Ingress

Water is among the most destructive contaminants for lubricants

Produces stable emulsions that impair lubrication

Disrupts the oil film between metal surfaces

Accelerates oxidation reactions

Promotes corrosion, especially in bronze or ferrous components

b) Solid Particles

Dust, sand, and grit: Cause abrasive wear

Metal shavings: Indicate wear-in-progress and exacerbate damage

Foreign greases: Mixing incompatible grease bases—like calcium and lithium—can cause chemical gelation

c) Incompatible Chemicals

Mixing oils with different base stocks or additive packages can trigger chemical instability

May cause filter clogging, sludge, or gel formation over time

For deeper insights into safe handling and usage, explore our related article: Key Considerations in Lubricant Safety Practices.

Case Study – Real-World Lubricant Failure

Scenario

In a metal drawing plant, gearbox lubricants degraded to a paste-like state. Testing revealed

High water content

Silicon contamination from dust ingress

Calcium levels exceeding 3100 ppm from calcium-based grease

Bearing temperatures spiking to 90°C, gearbox oil temperature reaching 100°C (well above the safe limit of 75–80°C)

Consequences

Rapid oxidation and chemical breakdown

Heavy sludge and adhesive deposits

Elevated metal particle counts (Cu, Sn, Fe) indicating severe wear

Conclusion

The combination of elevated temperature, moisture, and incompatible materials created a high-stress environment, drastically shortening lubricant and equipment life

Practical Measures to Prevent Industrial Oil Degradation

Temperature Management

Real-time monitoring via sensors

Use of thermal reference charts

Implementing effective cooling systems

Contamination Control

Use high-efficiency filters and maintain seals

Prevent moisture ingress by securing storage and transfer points

Avoid cross-contamination between incompatible lubricants

Routine Oil Analysis

Regular testing for water content, solids, and acidity

Adjust oil change schedules based on operating conditions

Operator Training

Teach safe handling and storage practices

Train staff to recognize early signs of degradation

By consistently applying these preventive measures, industries can extend lubricant service life, reduce maintenance downtime, and safeguard asset health

Want to strengthen your maintenance strategies? Read our guide: Understanding the Fundamentals of Lubrication.

Industrial Oil Degradation FAQ

Unusual temperature rise and darkened oil appearance are often the earliest indicators.

Every 500 operating hours or quarterly, whichever comes first.

Yes, synthetics generally offer higher thermal stability and better oxidation resistance.

Absolutely. High humidity increases the risk of moisture contamination and corrosion.

No. Mixing incompatible oils can cause chemical reactions that worsen degradation.

Particles create micro-abrasions on metal surfaces, leading to increased friction and faster oxidation.

Most lubricants degrade significantly above their recommended maximum, typically around 80°C for industrial gear oils.

Filtration can remove particles and water but cannot reverse chemical breakdown.

Mining, steel, food processing, and power generation face higher risks due to harsh conditions.

Sensors track real-time viscosity, temperature, and contamination, enabling early intervention.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us

no comment