Transformer oil, also referred to as insulating oil, remains an indispensable functional fluid in liquid‑filled power transformers. It performs multiple critical roles, including electrical insulation, heat transfer, arc suppression, and diagnostic fault indication through dissolved gas signatures. The reliability, efficiency, and service life of power transformers are directly dependent on the physicochemical stability of the oil and its interaction with solid insulation materials. This article presents a comprehensive industrial and academic review of transformer oils, covering their classifications, functional roles, physicochemical properties, aging mechanisms, diagnostic techniques, maintenance protocols, reclamation technologies, additive formulation strategies, and emerging innovation trends. Emphasis is placed on aligning practical engineering decisions with international standards and real‑world operational constraints in modern power systems.

1. Introduction

Transformer oil has played a foundational role in electrical power engineering for over a century. From early oil‑filled transformers to today’s ultra‑high‑voltage and digitally monitored units, insulating fluids have evolved from simple hydrocarbon liquids into carefully engineered dielectric materials. Unlike solid insulation, transformer oil is a dynamic medium whose condition continuously changes under thermal, electrical, chemical, and mechanical stresses. As a result, oil quality directly governs dielectric reliability, cooling efficiency, and the aging rate of cellulose insulation.

In modern power grids, transformer failure carries significant economic, environmental, and safety consequences. Studies indicate that a majority of transformer failures are related to insulation system degradation, in which oil condition plays a central role. Consequently, transformer oil is no longer viewed as a passive consumable but rather as an actively monitored engineering asset. Utilities and manufacturers increasingly rely on advanced testing, online diagnostics, and improved oil formulations to extend transformer lifetime and reduce unplanned outages.

The growing penetration of renewable energy, higher power density transformers, urban substations, and stricter environmental regulations have further intensified the importance of proper oil selection and management. This review aims to provide a holistic understanding of transformer oil behavior, maintenance strategies, and future innovation opportunities to support informed industrial decision‑making.

Although transformer oil operates under unique electrical and thermal conditions, many of its functions are rooted in the fundamental principles of industrial lubrication. For a broader conceptual background, see

2. Functional Roles of Transformer Oil

2.1 Electrical Insulation

The primary function of transformer oil is to provide reliable electrical insulation between energized components, windings, and grounded structural parts. By completely displacing air from voids and impregnating solid insulation materials, the oil significantly suppresses the formation of electrical discharge paths and local field intensification. The dielectric strength of transformer oil is highly sensitive to moisture content, dissolved gases, and suspended particles; even trace levels of contamination can lead to a pronounced reduction in breakdown voltage. Effective control of oil purity is therefore essential for maintaining insulation integrity and preventing partial discharges or catastrophic dielectric failure.

2.2 Heat Dissipation and Cooling

Transformer oil is an effective heat transfer medium due to its relatively high specific heat capacity and ability to circulate within the transformer tank. Heat generated by copper losses in windings and core losses in magnetic steel is transported by the oil to radiators or cooling systems, where it is dissipated to the surrounding environment.

Viscosity is a key parameter governing oil circulation. Low viscosity enhances natural convection, improves cooling efficiency, and reduces hotspot temperatures. Conversely, excessive viscosity impedes flow, leading to localized overheating and accelerated insulation aging.

2.3 Moisture and Gas Scavenging

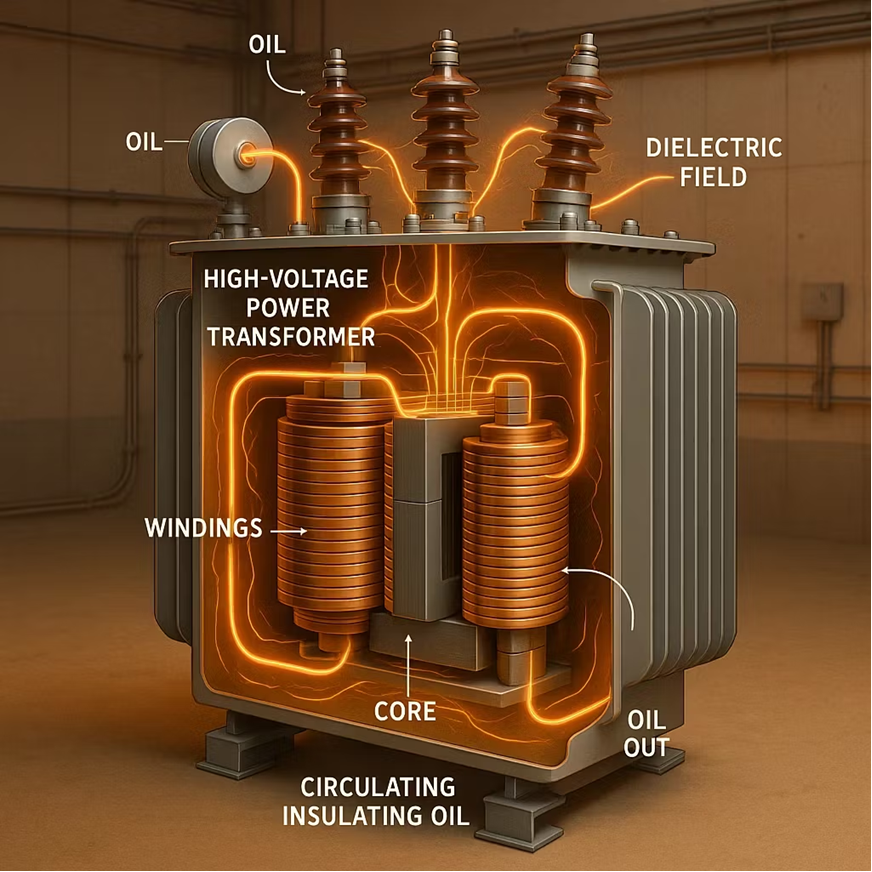

Oil serves as a reservoir for moisture and gases generated during transformer operation. Aging of cellulosic insulation releases water and carbon oxides, while electrical and thermal faults generate combustible gases such as hydrogen, methane, and acetylene. The oil absorbs and transports these by‑products, enabling diagnostic analysis while simultaneously influencing dielectric performance (Figure 1).

figure 1

3. Classification of Transformer Oils

3.1 Mineral Insulating Oils

Mineral oils are petroleum‑derived fluids refined to meet stringent electrical and chemical specifications. They remain the most widely used insulating liquids due to their favorable cost, good dielectric strength, and established performance history.

Mineral oils are generally categorized into naphthenic and paraffinic types. Naphthenic oils exhibit low pour points and good oxidation stability, making them suitable for colder climates. Paraffinic oils offer higher flash points and better thermal resistance but may be more prone to sludge formation during long‑term oxidation.

3.2 Synthetic Ester Oils

Synthetic esters are chemically engineered dielectric fluids designed for high fire safety and thermal endurance. Their very high flash and fire points significantly reduce fire risk, particularly in indoor substations or densely populated areas. Synthetic esters also exhibit good biodegradability and compatibility with sealed transformer designs.

3.3 Natural Ester Oils

Natural ester oils are derived from vegetable sources such as soybean, rapeseed, or palm oil derivatives. These fluids offer excellent environmental performance, including rapid biodegradation and low toxicity. A key advantage of natural esters is their high moisture saturation limit, which allows them to absorb water from cellulose insulation and slow paper degradation. However, their higher viscosity at low temperatures requires careful consideration in cold climates.

3.4 Silicone-Based Oils

Silicone oils provide exceptional thermal stability and fire resistance. Due to their high cost and specific handling requirements, they are typically reserved for specialized or high‑risk applications.

4. Physicochemical Properties and Performance Metrics

4.1 Viscosity

Viscosity plays a crucial role in the heat dissipation performance of transformer insulating fluids, as lower viscosity promotes better oil circulation and more efficient cooling. Conventional mineral oils typically exhibit kinematic viscosities of 8–10 cSt at 40°C, decreasing to approximately 2–3 cSt at 100°C, which facilitates effective natural and forced convection. In comparison, natural ester fluids (vegetable-based) generally have higher viscosities, ranging from 35–50 cSt at 40°C, though they experience a significant reduction at typical operating temperatures. Excessively high viscosity can impede fluid flow, leading to elevated winding and hotspot temperatures, accelerated insulation aging, and reduced overall transformer efficiency. International standards, such as IEC 60296 for mineral oils, primarily specify maximum viscosity limits at 40°C (≤12 cSt) to ensure reliable performance under varying thermal conditions.

4.2 Breakdown Voltage (BDV)

Breakdown voltage (BDV) is a fundamental parameter for assessing the dielectric strength of insulating oil and its ability to withstand electrical stress without failure. This property is highly sensitive to moisture content, particulate contamination, and the presence of dissolved or entrained gas bubbles, all of which promote electric field distortion and premature discharge initiation. For mineral insulating oils, BDV values typically exceed 30 kV under standard conditions as defined by ASTM D877, whereas vegetable‑based oils may initially exhibit lower values but can be enhanced through suitable additive packages. Experimental studies consistently demonstrate that increases in acidity or moisture content result in a pronounced reduction in breakdown voltage.

4.3 Flash and Fire Point

The flash point is an important safety parameter that characterizes the temperature at which oil vapors can momentarily ignite in the presence of an ignition source. A higher flash point indicates reduced fire risk by lowering the probability of vapor ignition during normal operation and fault conditions; however, it does not entirely prevent fire occurrence. Mineral transformer oils typically exhibit flash points above 140 °C, while ester‑based fluids possess significantly higher flash and fire points, improving fire safety in sensitive installations. Accordingly, flash point should be considered as a risk‑mitigation parameter rather than an absolute safeguard against fire.

4.4 Pour Point

The pour point defines the lowest temperature at which oil remains fluid. Low pour points are critical for transformers operating in cold climates to ensure startup reliability and continuous cooling.

4.5 Acidity and Oxidation Stability

Acidity increases as oil oxidizes during service. Elevated acid levels promote sludge formation, corrosion of metallic components, and degradation of cellulose insulation. Oxidation stability is therefore a key performance criterion for long‑term operation.

Acidity increases with aging, accelerating corrosion and reducing dielectric strength. Neutralization numbers should remain below 0.03 mg KOH/g for new oils. Moisture, even at 20-30 ppm, can halve breakdown voltage due to hydrolysis. Vegetable oils absorb more moisture but degrade slower oxidatively.

Regular testing via Karl Fischer titration is essential for maintaining efficiency.

4.6 Moisture Tolerance

Moisture tolerance varies significantly between oil types. Ester fluids can accommodate larger amounts of water without substantial dielectric degradation, offering protective benefits to paper insulation.

4.7 Interfacial Tension (IFT)

Interfacial tension (IFT) is a sensitive indicator of insulating oil purity and chemical stability. High IFT values, typically above 40 mN/m, indicate a clean oil with minimal polar contaminants and oxidation by‑products. As the oil ages or becomes contaminated by acids, sludge precursors, or moisture, surface‑active compounds accumulate and reduce IFT. Although interfacial tension does not directly determine dielectric strength, declining IFT values reliably signal early stages of oil degradation. Maintaining adequate IFT therefore supports transformer efficiency indirectly by preserving insulation cleanliness, minimizing instability in oil–paper interactions, and ensuring safe, continuous operation without unplanned outages.

5. Degradation Mechanisms

Transformer oil degradation results from the combined effects of thermal, electrical, chemical, and mechanical stresses. Thermal oxidation leads to the formation of acids, sludge, and varnish deposits. Hydrolytic degradation, particularly relevant in ester fluids, involves moisture‑driven chemical reactions. Electrical discharges such as partial discharges and arcing generate high‑energy reactions that rapidly decompose oil molecules.

Interactions between oil and paper insulation further complicate aging behavior. Cellulose degradation releases moisture and carbon oxides into the oil, while dissolved metal ions can catalyze oxidation reactions. Understanding these mechanisms is essential for designing effective maintenance strategies.

6. Standards and Quality Control

International standards define requirements for new oils, acceptance testing, and in‑service monitoring. Compliance with these standards ensures consistent performance, safety, and interoperability across manufacturers and utilities. Quality control during procurement and throughout service life is essential for minimizing operational risk.

Key international standards include:

• IEC 60296 — Specifications for unused mineral insulating oils

• IEC 60422 — Supervision and maintenance of in-service oils

• ASTM D1816 / D877 — BDV testing

• ASTM D1533 — Water content (Karl Fischer)

• ASTM D974 — Acidity

• IEEE C57.104 — DGA interpretation

• IEC 60567 — Sampling & analysis of dissolved gases

7. Diagnostics and Online Monitoring

Continuous assessment of transformer oil condition is fundamental to maintaining dielectric integrity, mitigating cellulose insulation degradation, and extending transformer service life. Breakdown Voltage (BDV) testing is widely regarded as the primary screening tool for oil quality, with reductions commonly associated with moisture ingress, particulate contamination, and oxidative by-products. Complementary measurements of acidity, moisture content, and interfacial tension (IFT), together with Dissolved Gas Analysis (DGA), enable early identification of incipient faults such as localized thermal overheating, partial discharge activity, and electrical arcing. The accuracy of these diagnostics is highly dependent on proper oil sampling procedures, including the use of clean containers, prevention of air exposure, and sampling from zones with adequate oil circulation, as sampling errors may result in misleading condition assessments. In practical operation, periodic filtration for particulate removal and vacuum dehydration for moisture reduction are recommended to restore dielectric strength and oxidative stability. When advanced degradation is indicated by elevated acidity, reduced IFT, sludge formation, or critical DGA fault gas patterns, a strategic decision between full oil reclamation—utilizing adsorptive clays, deep filtration, and chemical property restoration—or complete oil replacement must be made based on degradation severity, insulation paper condition, and life-cycle cost analysis. The deployment of online multi-parameter monitoring systems and real-time data integration supports condition-based and predictive maintenance strategies, significantly reducing diagnostic latency and enhancing transformer reliability, availability, and operational resilience(Figure 2).

Figure 2

8. Maintenance and Condition‑Based Management

Condition-Based Maintenance (CBM) is founded on the use of real-time operational data to predict failures before they occur. By integrating information from online Dissolved Gas Analysis (DGA), moisture sensors, temperature monitoring, and oil quality indicators, CBM enables optimized maintenance planning and informed decision-making. This data-driven approach reduces unnecessary maintenance activities, minimizes the risk of unplanned outages, and extends transformer service life by shifting asset management strategies from time-based schedules to condition-based interventions.

Many degradation mechanisms observed in transformer oils—such as oxidation, acidity increase, and sludge formation—are also common challenges across industrial lubrication systems. For a broader, cross‑industry perspective on this topic, see

[Preventing industrial oil degradation: causes, effects, and practical solutions]

9. Oil Reclamation and Life‑Extension Technologies

Oil reclamation processes are employed to restore insulating fluid quality and extend service life. Vacuum dehydration and heating remove dissolved moisture and gases. Adsorbents such as activated alumina and fuller’s earth eliminate acids, polar compounds, and oxidation by‑products. Filtration removes solid contaminants, while reinhibition restores antioxidant protection. Advanced catalytic regeneration and hydro‑processing techniques further improve oil stability and purity. Reclaimed oil may be reused if it meets relevant dielectric and chemical requirements specified in IEC 60296.

10. Comparative Analysis: Mineral Oil and Alternatives

Mineral oil has traditionally served as the primary insulating and cooling fluid in power transformers due to its low cost, suitable viscosity, and well‑established performance record. However, increasing safety and environmental expectations have led to broader consideration of alternative fluids. Synthetic esters provide excellent fire safety and strong thermal stability, making them suitable for demanding applications. Natural esters offer high biodegradability and a greater ability to absorb moisture, which can improve the lifespan of cellulose insulation. Silicone fluids deliver exceptional fire resistance and chemical stability, though their higher cost limits widespread use. Understanding these fluid categories helps asset managers choose the most appropriate option based on safety, environmental requirements, and operational conditions.

11. Additives, Formulation Engineering, and Innovation Trends

Additives are essential for enhancing the stability and service life of dielectric fluids. Phenolic and aminic antioxidants suppress acid and sludge formation, pour point depressants improve low-temperature performance, and anti-sludge additives together with metal deactivators reduce degradation and catalytic oxidation. In parallel, the development of hybrid fluids and advanced esters, supported by emerging nanotechnology and real-time monitoring approaches, reflects a clear shift toward safer, more durable, and environmentally compatible transformer insulating fluids.

12. Environmental and Safety Considerations

Environmental regulations and fire safety requirements strongly influence fluid selection in modern installations. Natural and synthetic esters offer clear advantages in environmentally sensitive areas and urban substations. However, lifecycle assessment, material compatibility, and economic factors must be evaluated holistically.

13. Future Outlook

The future of transformer oil technology lies in the integration of advanced materials, real‑time diagnostics, and data‑driven asset management. As power systems evolve toward higher efficiency and sustainability, insulating fluids will continue to play a critical supporting role.

14. Conclusions

Transformer oil is a critical component in ensuring the reliability and safe operation of power transformers by providing electrical insulation, efficient heat dissipation, arc suppression, and condition monitoring through dissolved gas analysis. Mineral oils remain dominant due to their economic advantages, while ester-based fluids offer superior fire safety and environmental compatibility, and silicone fluids are reserved for specialized applications. Compliance with IEC, IEEE, and ASTM standards enables advanced diagnostics, including DGA and online monitoring, facilitating predictive maintenance and life-extension strategies through oil reclamation and improved formulations. Looking ahead, the development of blended dielectric fluids and intelligent monitoring systems will play a pivotal role in addressing the challenges of renewable energy integration and increasingly stringent environmental requirements, making proactive and balanced transformer oil management essential for resilient and efficient power grids.

Frequently Asked Questions

Transformer oil governs both dielectric integrity and thermal performance. Degraded oil accelerates cellulose paper aging by increasing moisture content, acidity, and local hotspot temperatures. Empirical studies show that maintaining low moisture and acidity levels in oil can significantly slow paper depolymerization, which is the dominant life‑limiting factor of power transformers. In practice, oil quality management indirectly defines transformer service life.

No. BDV is a valuable screening parameter but must be interpreted alongside complementary tests such as moisture content, acidity, interfacial tension (IFT), and Dissolved Gas Analysis (DGA). Oil may exhibit adequate BDV while oxidation by‑products or incipient fault gases are already present. A multi‑parameter diagnostic approach provides a more reliable assessment of insulation health and operational risk.

Even moisture concentrations as low as 20–30 ppm can drastically reduce dielectric strength due to field distortion and bubble formation under electrical stress. Additionally, moisture migrates between oil and cellulose insulation depending on temperature, making transient conditions particularly risky. Effective moisture control therefore requires both oil dehydration and long‑term paper insulation management.

Ester fluids have a much higher moisture saturation limit than mineral oils, enabling them to absorb water from cellulose insulation. This moisture redistribution slows paper hydrolysis and extends insulation life. While ester oils may have higher viscosity, their enhanced moisture tolerance and thermal endurance can yield longer transformer lifetime when properly engineered.

Oil reclamation is technically justified when acidity, IFT, and dielectric properties can be restored without irreversible paper degradation. If DGA patterns indicate stable operation and paper condition remains acceptable, reclamation offers a cost‑effective life‑extension strategy. Complete oil replacement is typically required only when contamination, severe oxidation, or insulation damage exceeds recoverable limits.

IFT is highly sensitive to polar oxidation by‑products and surface‑active contaminants. A declining IFT often precedes visible sludge formation and dielectric failure, making it an effective early warning parameter. Although it does not directly measure electrical strength, IFT trends provide valuable insight into oil cleanliness and oxidation kinetics.

DGA is a powerful diagnostic tool but relies on correct sampling, trending, and context‑based interpretation. Single measurements may be misleading, especially after load changes or oil treatment. Accurate fault diagnosis requires trending over time, correlation with operating conditions, and reference to established standards such as IEEE C57.104.

Additives such as antioxidants, metal deactivators, and pour‑point depressants slow oxidation, reduce catalytic degradation, and maintain fluidity under cold conditions. However, additive depletion occurs during service, making reinhibition an essential component of oil life management. Poor additive balance can be as detrimental as additive absence.

Online monitoring enables continuous detection of moisture, gas generation, and thermal anomalies, reducing diagnostic latency compared to periodic laboratory testing. When integrated with condition‑based maintenance strategies, real‑time oil monitoring improves reliability, optimizes maintenance scheduling, and minimizes the risk of catastrophic transformer failure.

Modern asset management recognizes transformer oil as an evolving component of the insulation system. Its chemical state, interaction with solid insulation, and response to operational stress directly affect reliability and safety. Active monitoring, diagnostics, and treatment position transformer oil as a controllable variable rather than a passive consumable.

Stricter environmental and fire safety regulations increasingly favor ester‑based and high‑flash‑point fluids, especially in urban and environmentally sensitive regions. Selection decisions must balance ecological impact, fire risk, performance requirements, and total lifecycle cost to achieve regulatory compliance without compromising reliability.

Future developments include hybrid insulating fluids, improved ester formulations, advanced additive systems, nanotechnology‑enhanced dielectrics, and AI‑assisted condition monitoring. These innovations aim to improve fire safety, environmental performance, and predictive maintenance capabilities in increasingly stressed power networks.

References

· Heathcote, M. J. (2007). The J & P Transformer Book (13th ed.).

· Oommen, T. V. (2002). Vegetable oils for liquid-filled transformers. IEEE Electrical Insulation Magazine, 18(1), 6–11.

· Fernández, I., et al. (2013). Comparative evaluation of alternative fluids for power transformers. Electric Power Systems Research, 98, 58–69.

· AXA XL Risk Consulting. (2020). Transformer Dielectric Fluids—Fire and Risk Considerations.

· Cargill. (2020). Transformer power factor and FR3 fluid – Reference Data.

· MGM Transformers. (2025). Installation, Operation & Maintenance Manual – Liquid Filled Transformers.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us

no comment