Introduction

In any lubricated mechanical system, from heavy-duty industrial compressors to high-speed automotive engines, the quality of the lubricating oil directly impacts equipment performance, energy efficiency, and service life. Industrial oil filtration plays a crucial role in maintaining this oil quality by preventing the accumulation of harmful contaminants. Oil contamination is widely recognized as a major contributor to premature component wear, rising maintenance costs, and unplanned downtime. Even micron-sized particles can generate abrasive wear, accelerate corrosion, or cause coating degradation inside precision components.

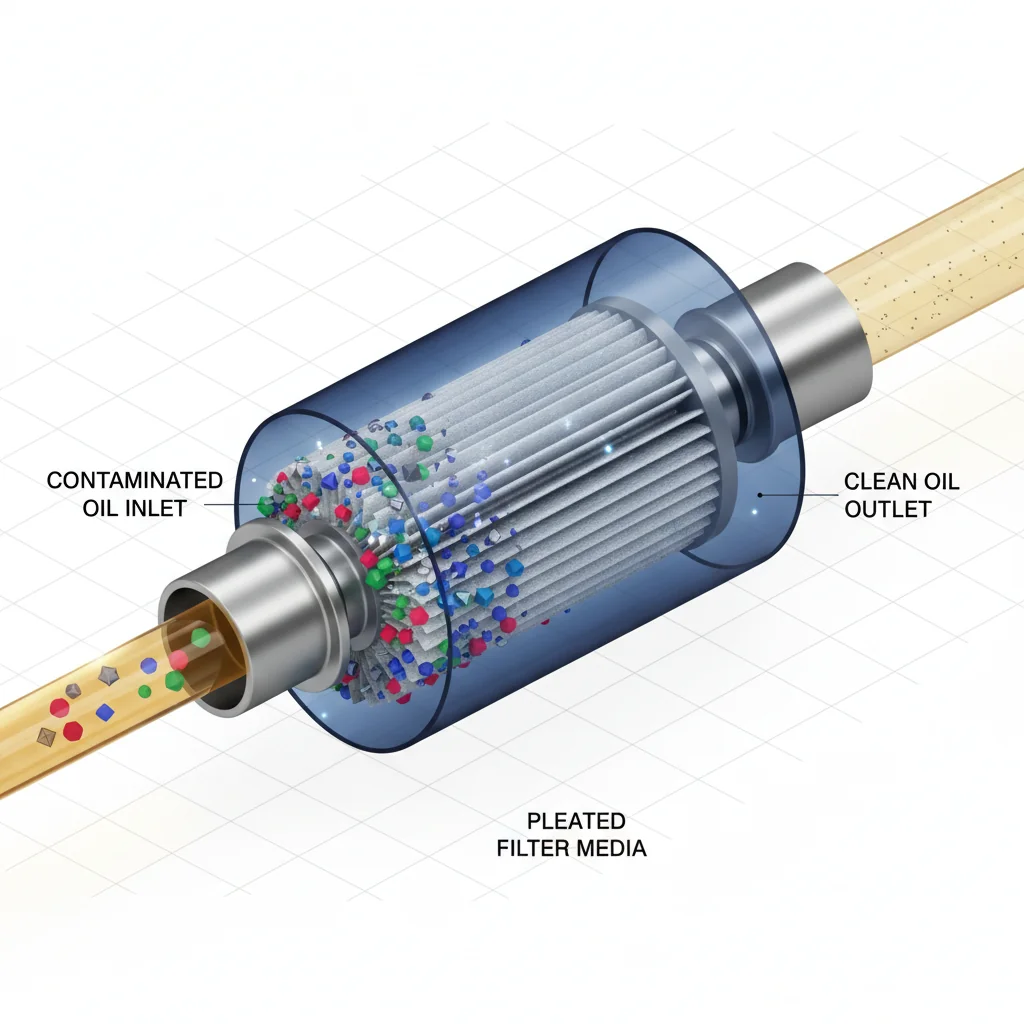

Oil filtration systems act as the first line of defense, continuously removing solid particulates and, in some cases, water or chemical contaminants from circulating oil. Effective filtration not only safeguards moving parts but also protects the oil’s additive package, thereby preserving its physical and chemical stability. In the industrial context, properly specified and maintained filters are not optional; they are an operational necessity.

When implementing contamination control measures, emphasizing industrial oil filtration efficiency ensures sustained lubricant performance under heavy operating loads.

Main Types of Industrial Oil Filtration

Oil filters can be categorized into several distinct types, each adapted to specific operating conditions and performance requirements.

Full‑flow filters are positioned directly in the main lubrication line, treating the total volume of oil before it reaches critical contact surfaces. Designed for minimal restriction, they deliver continuous protection under all load conditions but may permit very fine particles to bypass if the filtration rating is relatively coarse.

Bypass filters are configured to clean only a small fraction of the circulating oil at a time, yet with extremely high efficiency. By diverting part of the oil flow through dense or depth‑type media, bypass units capture ultra‑fine particles that full‑flow systems may miss, without imposing significant pressure loss on the main line. This design is particularly valuable in high-load diesel engines and hydraulic systems, where sustained oil cleanliness greatly prolongs component life and reduces maintenance intervals.

Duplex and simplex filters address operational flexibility. Duplex designs comprise two parallel housings containing independent elements; the operator can switch from one housing to the other during maintenance, keeping the filtration system active with no downtime. This approach is essential for mission-critical applications where halting oil flow is unacceptable. By comparison, simplex filters are single‑housing units with a straightforward design, suitable for equipment that can be stopped temporarily for scheduled servicing, offering a cost-efficient solution for intermittent‑duty machinery.

Back‑flushing filters are reusable filtration units designed for in-place cleaning by reversing the fluid flow to dislodge contaminants adhering to the filter media. This process requires temporary interruption of normal filtration; therefore, duplex configurations with parallel filters are often employed to ensure continuous operation during cleaning cycles. Back‑flushing may be internal, using part of the filtrate, or external, utilizing a separate cleaning fluid, with optional compressed air assistance for enhanced particle removal. Optimal system performance depends on correct sizing, contaminant capacity assessment, and pressure control parameters tailored to operational needs

Fine filtration units serve high-precision systems where extreme cleanliness is imperative, such as turbines or sensitive hydraulic circuits. Employing tubular or flat‑sheet elements, these units achieve sub-micron particle removal, meeting or exceeding stringent ISO cleanliness standards. Such performance is crucial for vibration-sensitive equipment, in which even microscopic debris can rapidly degrade bearings, seals, or precision-machined surfaces.

Through proper selection and application of these filter types, maintenance teams can tailor oil cleanliness control to match system demands, ensuring both operational reliability and cost-effective maintenance schedules.

Key Criteria for Selecting the Best Oil Filter

Choosing the most suitable Industrial Oil Filtration for a lubrication system requires a careful balance between performance specifications, operating conditions, and long-term maintenance objectives. The first consideration is filtration efficiency, typically quantified through a Beta Ratio or micron rating. This parameter indicates the filter’s ability to capture particles of a given size and should match the predominant contaminant profile in the system. A filter with too coarse a rating may allow damaging debris to circulate, while an overly fine element can cause excessive restriction if not paired with an appropriate flow capacity.

Flow capacity is equally important, as the filter must handle the system’s nominal oil flow without generating an unacceptable differential pressure. Excessive restriction can trigger bypass valve operation or starve components of lubrication, leading to accelerated wear. Engineers must verify that the selected filter maintains stable pressure across the element during all operating conditions.

The media material determines not only filtration performance but also durability under environmental stress. Common choices include cellulose for economical, general-purpose use; synthetic fibers for high dirt-holding capacity and fine particle removal; and wire‑mesh screens for applications requiring washable elements. Material selection should account for operating temperature, chemical compatibility with the lubricant, and resistance to collapse under pressure surges.

The operating environment strongly influences filter design requirements. In high-temperature compressors, heavy-duty diesel engines, or marine propulsion systems, heat-resistant elastomer seals and reinforced housings are essential. Exposure to corrosive environments, vibration, or shock loading demands robust build quality to ensure reliability throughout the service interval.

Serviceability is another key factor, especially in remote or hard-to-access installations. Filters that allow quick element changes, straightforward cleaning, or automated back‑flushing reduce maintenance downtime and ensure consistent system protection. Evaluating the ease of servicing can prevent prolonged exposure to unfiltered oil during maintenance procedures.

Finally, the cost‑versus‑lifecycle balance should guide procurement decisions. While self-cleaning or ultra-high‑efficiency units may entail a higher upfront investment, they often reduce total maintenance expense by extending oil life, decreasing change frequency, and preventing costly equipment failures. Considering lifecycle costs rather than just purchase price ensures the filter remains a cost-effective asset over time.

Filter selection should also consider the type of fluid used. For instance, in systems that employ evaporative oils for metalworking or component cleaning processes, the filter must be capable of capturing suspended metallic particles and oil‑vapor residues without causing a significant pressure drop.

Oil Filters vs. Fuel Filters, Functional Comparison

While both oil and fuel filters serve the fundamental role of protecting machinery from harmful contaminants, their operational contexts and design priorities differ substantially.Industrial Oil Filtration are integrated into lubrication circuits, removing particles such as wear debris, dust, and soot to maintain a clean oil film between moving surfaces. Their media are engineered to handle high‑viscosity fluids, withstand thermal cycling, and retain contaminants under sustained pressure without premature collapse.

In contrast, fuel filters operate within the fuel delivery system, where preventing abrasive particles, rust, and water from entering injectors or carburetor jets is critical. They typically use fine-pore elements or multi-stage separation designs, often incorporating water‑separating stages in diesel applications. Fuel filters must manage low‑viscosity fluids at relatively high flow rates, preserving precise metering and atomization needed for combustion efficiency.

The most important distinction lies in the contaminant profile and fluid properties: oil filters target solid particulates and oxidation by‑products in a lubricating environment, whereas fuel filters combat both solids and immiscible liquids in a chemically sensitive, combustion-oriented medium. Choosing the correct filter type for each system ensures maximum component longevity and optimal performance.

Conclusion

Effective oil filtration is not simply a supporting component of a lubrication system; it is a core element of an asset’s reliability framework. Selecting the correct filter type, applying the right media technology, and matching specifications to the operating environment directly influence wear rates, energy efficiency, and oil lifespan. Equally, adherence to rigorous maintenance and inspection practices ensures that the filter continues to perform its protective role without introducing risks such as bypass activation, media collapse, or contamination ingress.

In industrial contexts where downtime carries substantial financial and operational consequences, treating filtration as an integral part of the maintenance strategy-rather than a consumable item-delivers measurable benefits: reduced unplanned stoppages, extended component life, and optimized total cost of ownership.

Understanding how to classify and select the right oil filter is only part of the equation. To gain deeper insight into the industrial oil filter failure causes and prevention methods, explore our detailed guide on performance challenges, maintenance strategies, and preventive measures.

Frequently Asked Questions – Industrial Oil Filtration

Industrial oil filtration eliminates solid particles, sludge, varnish, and moisture that degrade lubricating oil and damage precision surfaces.

Replacement intervals depend on contamination levels and system design, but monitoring differential pressure across the filter gives the most accurate timing.

The Beta Ratio measures filtration efficiency by comparing particle counts upstream and downstream — higher ratios mean finer, more reliable contaminant removal.

Yes. Consistent filtration preserves additive integrity, slows oxidation rates, and drastically extends lubricant service life, lowering total operating costs.

Full-flow filters handle 100% of the oil stream for continuous protection, while bypass filters treat a smaller portion with ultra-fine filtration for precision cleaning.

Synthetic fibers generally outperform cellulose by holding more contaminants and maintaining stable flow under high-temperature or high-pressure conditions.

It reverses the oil flow to dislodge trapped particles from the media. This allows reusable filter elements to operate longer before manual servicing is needed.

High-viscosity oils require filters with adequate flow capacity and stronger housings to prevent pressure drops or bypass valve activation.

Sensors and particle counters enable real-time cleanliness tracking, predictive maintenance, and immediate alerts for filter clogging or bypass conditions.

By maintaining cleaner oil, filtration protects assets from wear and downtime, reduces oil change frequency, and maximizes the value of every maintenance cycle.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us

no comment