Conveyor Chain Oil

Our best services and products are at your disposal. For more information or to place an order, just click the button below right now and take the first step!

Conveyor Chain Oil

Share This Product:

Product Introduction

Conveyor Chain and Its Applications

Conveyor chains are one of the key components of material transportation systems used across various industries. These chains are designed for moving heavy loads and connect different stages of production, facilitating the transfer of raw materials, semi-finished products, or final goods.

The application of conveyor chains extends to industries such as automotive assembly, food and beverage production, pharmaceutical manufacturing, and large-scale warehousing. For example, in the food industry, conveyor chains are used to transport products during various stages of production, such as baking, packaging, and quality inspection, all while maintaining precision and hygiene standards. In the logistics sector, conveyor chains enhance efficiency by simplifying item handling for sorting and storage, thereby optimizing supply chain operations.

Conveyor Chain Oil and Its Importance

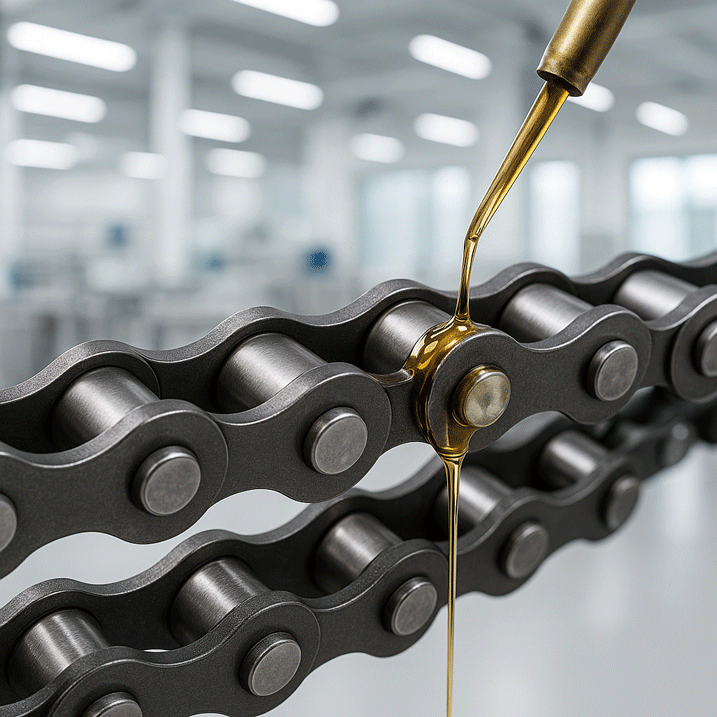

Conveyor chain oil is one of the essential components of conveyor chain systems, playing a key role in ensuring optimal performance. Conveyor chains often operate under high loads, extended usage, and exposure to various environmental conditions, all of which can lead to increased friction, wear, and deterioration. Conveyor chain oil is specifically designed to address these challenges, enabling the chains to perform effectively even in harsh conditions while reducing the need for repairs, lowering maintenance costs, and extending the lifespan of the equipment.

Without proper lubrication, conveyor chains wear out quickly and experience premature failures, resulting in costly repairs and system downtime. Additionally, chains lacking lubrication require more force to operate, leading to reduced efficiency and increased operational costs.

The significance of conveyor chain oil also lies in its ability to withstand challenging environmental conditions. For instance, conveyor systems in industries such as food production and pharmaceuticals are often exposed to high temperatures, strong cleaning chemicals, and frequent washdowns. Under such conditions, a suitable chain oil ensures that the chains maintain their performance even under these demanding conditions. Similarly, conveyor chains used outdoors in sectors like mining and construction are exposed to dust, soil, and water. In these environments, chain oil protects against contamination and ensures smooth operation.

Another key aspect of conveyor chain oil is its contribution to enhancing the durability of systems. Choosing the right oil can significantly extend the lifespan of the chain, preventing chemical degradation, corrosion, and mechanical stress. Proper lubrication ensures optimal equipment performance, minimizing the need for frequent maintenance while improving overall productivity.

Key Features of Eriss Kimia Pars Conveyor Chain Oil

The conveyor chain oil from Eriss Kimia Pars boasts the following features:

1-Wear Reduction

One of the primary functions of conveyor chain oil is reducing wear caused by friction between moving components. This feature is essential to minimize maintenance costs and prevent mechanical system failures. Eriss Kimia Pars conveyor chain oil is formulated to enhance the reduction of friction and wear.

2-Temperature Resistance

Conveyor chain oil must maintain its performance at extremely low and high temperatures. Whether the working environment is very cold or very hot, the oil should not solidify or evaporate. This feature, incorporated into Eriss Kimia Pars conveyor chain oil, is particularly critical in industries such as food production and pharmaceuticals, where prolonged exposure to high or low temperatures is common.

3-Appropriate Adhesion

Adhesion is a crucial factor in chain oil because it determines how well the oil adheres to the chain surface. Eriss Kimia Pars conveyor chain oil exhibits strong adhesion, remaining securely in place despite chain movement or environmental influences.

4-Oxidation Resistance

Industrial environments are prone to oxidation caused by heat, oxygen, and contaminants. Eriss Kimia Pars chain oil is highly resistant to oxidation, retaining its effectiveness over time. This feature prevents oil breakdown and protects conveyor chains from rust and corrosion.

Advantages of Using Eriss Kimia Pars Conveyor Chain Oil

- Smooth Operations: Conveyor systems can run with fewer disruptions since the likelihood of chain breakage is significantly reduced.

- Extended Lifespan: By using Eriss Kimia Pars conveyor chain oil, chains and many other components do not wear out quickly, resulting in a longer lifespan and reduced need for replacement.

- Lower Energy Consumption: By using Eriss Kimia Pars conveyor chain oil, you can reduce energy consumption, as a lubricated chain requires less energy compared to a chain that is either unlubricated or improperly lubricated.

- Cost Savings: You can reduce many of the costly repair and maintenance expenses associated with defective chains. Using Eriss Kimia Pars conveyor chain oil also prevents the risk of conveyor downtime caused by chain breakage, avoiding additional expenses.

- Higher Efficiency: Optimal lubrication reduces friction, improving the system’s overall efficiency.

- Simplified Maintenance Efforts: Regular lubrication reduces the effort and costs involved in maintaining conveyor chains.

Chain manufacturers typically use grease or petroleum jelly as the initial lubricant. For example, non-flammable greases such as Molykote 1102 are used, which are not considered cost-effective. Eriss Kimia Pars conveyor chain oil offers similar performance to these greases.

Additionally, Eriss Kimia Pars provides systematically formulated lubricants made from high-quality raw materials that meet the latest regulatory requirements, ensuring operator health, safety, and environmental protection. To order Eriss Kimia Pars conveyor chain oil and receive free consultation, contact our expert team today.

Recommended Reading Article

Product Features

- Advanced Wear Protection

- Excellent Thermal Stability

- Superior Adhesion to Metal Surfaces

- High Oxidation Resistance

- Corrosion Inhibition

- Low Friction Performance

- Non-toxic & Food Safety Compliance

Proper storage of conveyor chain oil is essential to maintain its performance and ensure its extended shelf life. Storing the oil under inadequate conditions can lead to changes in its chemical and physical properties, resulting in compromised lubrication and possible equipment failures. To safeguard the quality of conveyor chain oil, it is recommended to store it in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat. Exposure to high temperatures or sunlight may accelerate oxidation and degradation, while excess humidity can introduce moisture into the oil, affecting its effectiveness.

The container should always be kept tightly closed to prevent contamination from dust, dirt, or water, and to avoid the evaporation of essential components. It is crucial to store the oil in its original, clearly labeled containers, and to avoid mixing it with other lubricants or foreign substances, as this can alter its formulation and functionality.

Temperatures should be maintained between 5°C and 40°C (41°F to 104°F) to ensure the optimal physical and chemical stability of the oil. Sudden temperature fluctuations, as well as freezing conditions, should be avoided as they can cause separation or thickening of the oil. Additionally, conveyor chain oil should be stored away from strong acids, alkalis, and oxidizing agents to prevent chemical reactions that could degrade its properties.

By following these scientific and professional storage guidelines, users can maximize the efficiency and lifespan of their conveyor chain oil and, consequently, protect the reliability and performance of their equipment.

Packaging

Conveyor chain oil is packaged and supplied in standard 208-liter drums.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us