Aluminum Drawing Oil

Our best services and products are at your disposal. For more information or to place an order, just click the button below right now and take the first step!

Aluminum Drawing Oil

Share This Product:

Product introduction

Aluminum Drawing Oil

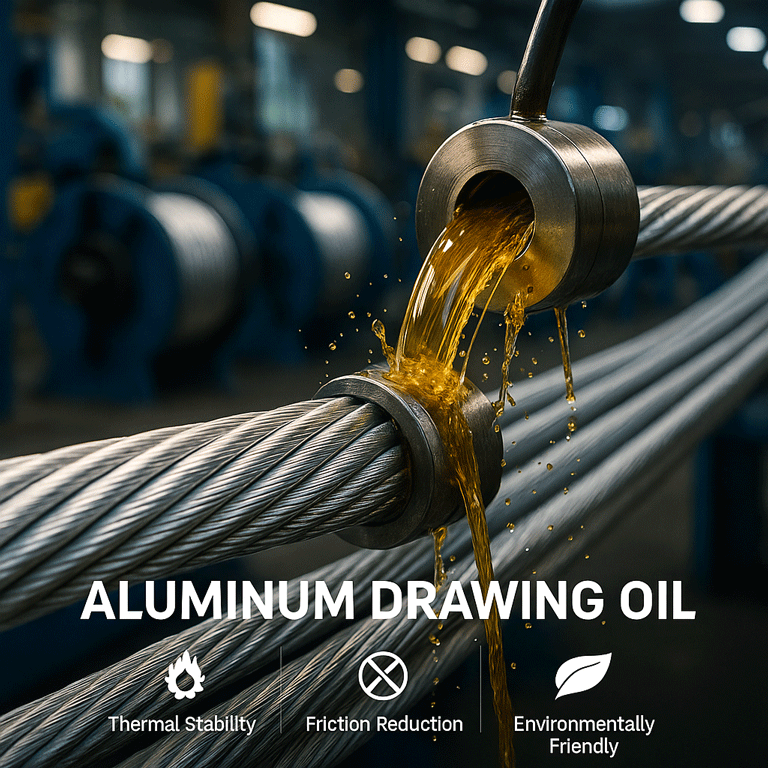

In the aluminum production process, the use of aluminum drawing oil is highly important. These oils act as intermediaries to reduce friction and heat, playing a key role in improving the quality of aluminum products. Aluminum drawing oil is made from the best base oils and is used for the production of aluminum cables. This oil is produced both in water-soluble and pure forms. Due to its unique properties and anti-wear and anti-corrosion features, aluminum drawing oil leads to improved drawing parameters and increased product quality.

Features of Aluminum Drawing Oil:

1. Reducing Friction

Aluminum drawing oil helps reduce friction between the metal surface and tools, facilitating the drawing process and resulting in less heat generation and wear.

2. Thermal Stability

These oils must be stable at high temperatures and maintain their properties under various thermal conditions. Thermal stability helps prevent decomposition and loss of performance.

3. Excellent Lubrication Properties

High lubrication properties enable easy movement of parts, reducing the need for excessive force. 4. Compatibility with Aluminum

Aluminum drawing oil must be completely compatible with aluminum and its alloys. Corrosion and oxidation of the aluminum surface can reduce the lifespan of equipment. (Reducing the useful life of the machine.)

5. Prevention of Oxidation

Some drawing oils have anti-rust properties that prevent the oxidation and rusting of aluminum. This is especially important when storing materials in humid conditions.

6. Uniform Coating

These oils should be able to provide a uniform coating over the surface to minimize foaming that may occur during production.

7. Cooling Capability

Drawing oil must be effective enough to provide efficient cooling and thus minimize heat damage.

8. Environmental Compatibility

Given environmental concerns, drawing oils should be environmentally friendly and safe for health, to limit negative impacts on workers and the environment.

The use of bio-based drawing oils without harmful chemicals can help reduce environmental impact and be safer for workers.

9. Cost-Effectiveness

The choice of drawing oil should be economically viable and help reduce overall production costs.

By using the aluminum drawing oil produced by Eriss Kimia Pars Company, you can improve the quality and efficiency of your products.

10. Improvement of Final Product Quality

Drawing oil creates a protective film layer, preventing the absorption of contaminants and dust, thus improving the surface quality of the final product. This can lead to better appearance and higher technical specifications in the finished product.

11. Increased Production Efficiency

By reducing friction and heat, drawing oil makes the production process easier and faster, resulting in increased productivity and reduced production time.

12. Reduced Maintenance and Repair Costs

Using suitable drawing oil can help reduce the wear of tools and machine parts, which leads to lower maintenance and repair costs.

13. Reduced Risk of Failures and Errors

By optimizing the production process and reducing wear and failure, drawing oil helps reduce the risk of breakdowns and production errors, thus enhancing the manufacturer’s reputation.

14. Facilitation of Forming Processes

Drawing oil helps facilitate various forming and drawing processes, which can result in greater variety in final products.

Overall, using aluminum drawing oil not only improves the quality and efficiency of the production process but also reduces costs and increases equipment lifespan.

Choosing the right aluminum drawing oil can have a significant impact on the quality and productivity of aluminum products. At Eriss Kimia Pars Company, we strive to ensure that the oil

we produce is of the highest quality and helps improve your performance.

Product feature

- Excellent Lubrication and Friction Reduction

- High Thermal Stability

- Strong Anti-Wear and Anti-Corrosion Properties

- Superior Compatibility with Aluminum and Its Alloys

- Efficient Cooling and Heat Dissipation

- Environmental Friendliness and Worker Safety

- Cost-Effectiveness and Maintenance Reduction

Proper storage of Aluminum Drawing Oil is essential to preserve its chemical stability, performance, and shelf life. To achieve the best results and ensure operator safety, it is recommended to strictly follow these scientific guidelines:

Aluminum Drawing Oil should always be stored indoors, in original, airtight, and corrosion-resistant containers. Storage drums or containers should be tightly sealed after each use to prevent the entry of air, moisture, and contaminants that can degrade the oil’s properties. Prolonged exposure to direct sunlight or ultraviolet radiation should be strictly avoided, as this can accelerate oxidation and negatively affect lubricant quality.

The optimal storage temperature for Aluminum Drawing Oil is between 5°C and 35°C (41°F to 95°F). Fluctuations outside this range can lead to increased viscosity, phase separation, or degradation of key additives. The storage space should have controlled humidity to prevent condensation and the formation of water in the product, which may result in reduced lubrication, corrosion, or microbial growth.

It is important to keep Aluminum Drawing Oil away from sources of heat, open flames, or sparks to minimize fire risk. Never store near oxidizers, acids, or reactive chemicals, as unintended chemical reactions could occur. To maintain traceability and prevent accidental mixing, ensure that containers are clearly labeled with product name, lot number, and expiry date. Always keep the containers upright, and inspect regularly for leaks, rust, or any signs of container deterioration.

In addition, the storage area must be clean, free of dust, and equipped with appropriate spill containment measures to address possible leaks. Utilize first-in, first-out (FIFO) inventory management to ensure older stock is used before newer deliveries, preventing prolonged storage.

Under proper storage conditions, Aluminum Drawing Oil retains its optimal characteristics for at least 12 months. For longer storage, periodic laboratory testing is recommended to verify the oil’s quality before use.

Summary Checklist:

Store in original, sealed, corrosion-resistant containers.

Keep at 5°C to 35°C (41°F to 95°F); avoid temperature fluctuations.

Prevent exposure to direct sunlight, moisture, and contaminants.

Isolate from oxidizing agents, acids, heat sources, and open flames.

Store in a clean, dry, and well-ventilated area with spill containment.

Clearly label all containers and keep upright at all times.

Inspect stocks regularly and practice FIFO inventory management.

By rigorously following these scientific storage recommendations, you can maximize the stability, efficiency, and operational safety of your Aluminum Drawing Oil during the entire storage period.

Packaging

Aluminum drawing oils are packaged and supplied in standard 208-liter drums.

Aluminum Drawing Oil FAQ

Why is aluminum drawing oil essential in cable and wire production?

Aluminum drawing oil is vital for minimizing friction and heat during wire and cable forming. This ensures smooth processing, protects equipment, and results in products with a superior finish.

What makes a drawing oil suitable for use with aluminum?

A suitable drawing oil must be fully compatible with aluminum alloys, offer high thermal stability, strong anti-wear protection, and must not contribute to oxidation or corrosion on the metal’s surface.

What is the difference between pure and water-soluble aluminum drawing oil?

Pure drawing oils are used undiluted and provide maximum lubrication. Water-soluble (emulsifiable) versions can be mixed with water to deliver increased cooling, which is helpful for high-speed or high-temperature operations.

How does aluminum drawing oil improve production efficiency?

By lowering tool friction and dissipating heat, drawing oil enables higher processing speeds, fewer stoppages, and longer die life, all contributing to more efficient manufacturing.

Does aluminum drawing oil offer protection against rust and corrosion?

Yes, premium aluminum drawing oils are formulated with additives that actively prevent rust and corrosion, protecting both the product and processing equipment.

How should aluminum drawing oil be stored for best results?

Store the oil in tightly sealed, corrosion-proof containers away from direct sunlight, heat, and moisture. Maintain storage temperatures between 5°C and 35°C for best stability and performance.

How can I tell if the aluminum drawing oil has deteriorated?

Changes in texture, color, separation, or the presence of unusual odors suggest the oil may be contaminated or degraded and should be replaced to protect your machinery.

Are there environmentally friendly options for aluminum drawing oil?

Yes, several modern formulations use bio-based components and exclude harmful chemicals, helping to reduce workplace and environmental risks.

What are the main benefits of using high-quality aluminum drawing oil?

Improved product quality, greater tool lifespan, reduced maintenance needs, stable operation, and a smoother end product are key benefits of choosing a high-grade drawing oil.

Should I consider cost-effectiveness when choosing drawing oil?

Absolutely. Selecting an efficient oil can reduce tool wear, maintenance frequency, and production downtime—leading to significant long-term savings despite the initial investment.

What role do anti-wear additives play in aluminum drawing oil?

Anti-wear additives form a protective film on metal surfaces, reducing abrasion, preventing scoring, and extending the life of both dies and tooling.

Why is it important for drawing oil to have low foaming properties?

Oils with low foaming tendencies create a more uniform coating during production and minimize air entrapment, leading to higher-quality aluminum products and trouble-free operations.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us