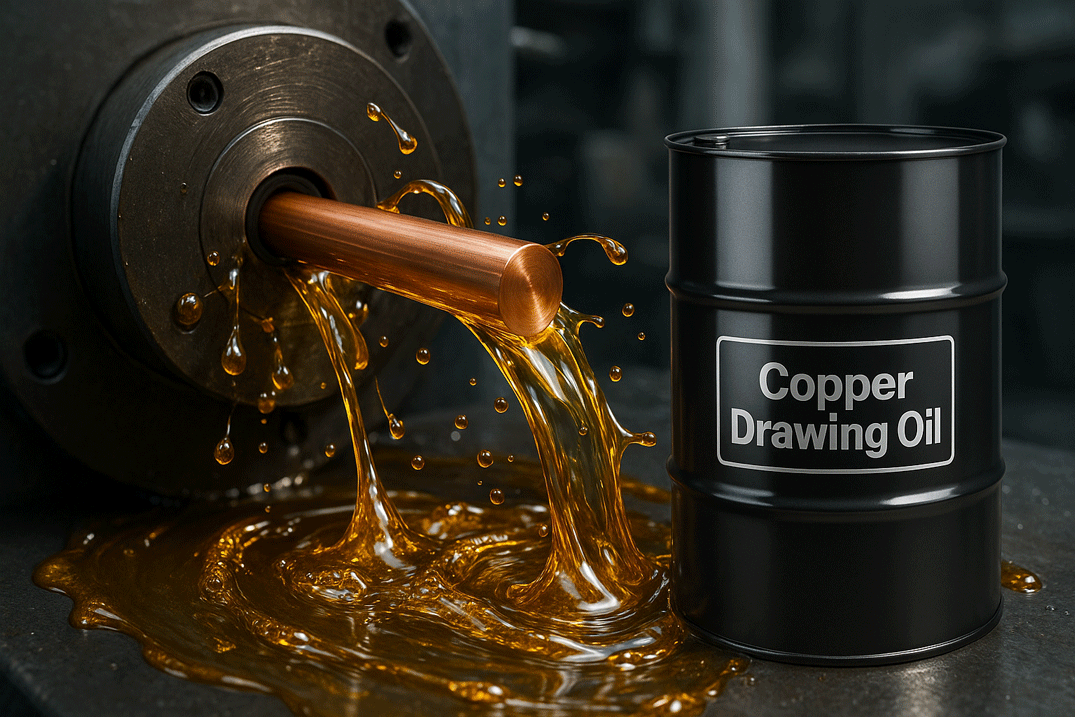

Copper Drawing Oil

Our best services and products are at your disposal. For more information or to place an order, just click the button below right now and take the first step!

Copper Drawing Oil

Share This Product:

Product Introduction

What is Copper Drawing Oil?

Copper drawing oil is one of the most important consumables in the production of copper tubes, wires, and cables. This oil acts as both a lubricant and a coolant, and is used in cold forming processes. By reducing the heat and friction caused by the drawing process, copper drawing oil increases the lifespan of the drawing machines and dies, and also improves the quality of the final product.

Types of Copper Drawing Oil:

– Mineral-based oils:

These oils are derived from crude oil refining and are traditionally the most common type of copper drawing oil. Their price is relatively lower, but they have lower thermal and oxidation stability compared to other types. This means they need to be changed more frequently and are more prone to contamination due to oil breakdown.

– Synthetic-based oils:

These oils are produced in laboratories and are usually classified as group IV and V oils. They offer much higher thermal and oxidation stability compared to mineral-based oils, resulting in longer service life and reduced frequency of oil changes. They also provide better lubrication and cooling properties. However, their price is higher. The new generation of synthetic oils, with more complex formulations and advanced additives, offers significant improvements in performance, including enhanced oxidation stability, better wear resistance, and reduced friction. These oils are ideal for high-tech applications, such as drawing ultra-fine wires.

– Emulsifiable oils:

These oils are used in the form of emulsions (a mixture of oil and water). They have higher cooling capability due to the presence of water and can sometimes help clean equipment better. However, careful attention must be paid to the oil-to-water ratio and the type of emulsifier used.

Oils containing special additives:

Many copper drawing oils contain additives to enhance specific performance properties, such as: – Anti-wear additives: to reduce wear and increase the lifespan of dies and equipment

– Anti-oxidation additives: to increase oil stability and prevent its breakdown

– Anti-rust additives: to prevent corrosion of copper equipment

The selection of a suitable copper drawing oil depends on various factors, including the type of copper, wire diameter, drawing speed, working temperature, and budget. Eriss Kimia Pars Company can provide technical consultation to help you select the best drawing oil.

Features of a High-Quality Copper Drawing Oil:

A good copper drawing oil should have the following characteristics: – Suitable viscosity

– High thermal and oxidation stability

– Excellent lubricating properties

– Anti-corrosion properties

– Proper cooling capability

– Environmental compatibility (if possible)

How to Select Copper Drawing Oil:

To choose the right copper drawing oil, you should consider: – Type of copper part

– Type of drawing machine

– Working temperature conditions

– Required standards

– Price and brand of the oil

Product Features

- Optimal Viscosity

- High Thermal and Oxidation Stability

- Excellent Lubrication Properties

- Anti-Corrosion Performance

- Effective Cooling Capability

- Enhanced Wear Resistance (Anti-Wear Additives)

- Eco-Friendly Formulation (Environmentally Compatible)

Proper storage of Copper Drawing Oil is essential to ensure its quality, performance, and longevity. Industrial oils are sensitive to environmental factors such as temperature, humidity, and contamination, so adopting proper storage methods is critical. Here are the key points to follow for maintaining the quality and effectiveness of copper drawing oil:

Storage Location:

Store the oil in a covered, dry location, protected from direct sunlight and rain to prevent physical and chemical changes caused by external environmental factors.

Temperature Control:

Keep the storage temperature within the manufacturer’s recommended range, typically between 10°C and 40°C. Extreme temperatures can degrade the oil’s properties, reducing its effectiveness.

Sealed Containers:

Always keep the container lids tightly closed when the oil is not in use. This prevents contamination from dirt, moisture, or debris and reduces the risk of oxidation over time.

Avoid Water Contamination:

Since water can significantly impact the oil’s performance, especially in lubrication and cooling, ensure the storage environment is free from leaks or high humidity.

Shelf Life Management:

Most Copper Drawing Oil products have a shelf life of at least one year if stored under proper conditions. Ensure the oldest stock is used first to prevent spoilage.

Regular Inspection:

Periodically inspect the oil for signs of contamination or decomposition, such as unusual odors, discoloration, or separation. Discard any oil showing these signs to avoid damaging equipment.

Proper Container Handling

Store the oil in its original sealed container, typically 208-liter metal drums, as provided by the manufacturer. Decanting the oil into smaller containers can increase the risk of contamination.

By following these guidelines, you ensure the oil retains its optimal performance, reduces maintenance costs, and improves the lifespan of equipment.

Packaging

Copper drawing oils are packaged and supplied in standard 208-liter drums.

Copper Drawing Oil FAQ

What is the primary function of copper drawing oil in the manufacturing process?

Copper drawing oil serves a dual role as both a lubricant and coolant during the copper wire and tube drawing process, helping to minimize friction, dissipate heat, and extend the life of machinery and dies.

Why is it important to choose the right type of drawing oil for copper processing?

Selecting the appropriate drawing oil ensures maximum equipment protection, consistent wire quality, and optimal operational efficiency, while also reducing maintenance and oil change frequency.

How do mineral-based and synthetic drawing oils differ?

Mineral-based oils are cost-effective and widely used, but offer lower durability in high-temperature or demanding applications. Synthetic oils, on the other hand, provide superior resistance to heat and oxidation, leading to longer intervals between oil changes.

Can copper drawing oil prevent rust and corrosion?

Yes, high-quality copper drawing oils are formulated with anti-corrosion additives that protect both the produced copper and the machinery against rust and oxidation.

What makes emulsifiable drawing oils unique?

Emulsifiable drawing oils are designed to blend with water, creating an emulsion that delivers enhanced cooling performance and helps keep equipment cleaner during operation.

How should copper drawing oil be stored to maintain its effectiveness?

Store the oil in its original sealed container, in a cool, dry place away from direct sunlight and moisture. Proper storage prevents contamination and preserves the oil’s chemical stability.

What are the warning signs that copper drawing oil should be replaced?

Indicators include changes in color, unusual odors, or visible separation of the oil components. Any signs of contamination or breakdown mean the oil should be replaced to avoid equipment damage.

Are there environmentally friendly copper drawing oils available?

Yes, some modern copper drawing oils are engineered with formulations that minimize environmental impact while still delivering strong lubrication and cooling properties.

How does the viscosity of drawing oil affect performance?

Appropriate viscosity ensures smooth metal deformation and efficient cooling during drawing. Oils with incorrect viscosity can result in uneven wire surfaces and increased equipment wear.

What technical support does Eriss Kimia Pars Company offer for copper drawing oil selection?

Our specialists provide personalized consultations to help customers choose the ideal drawing oil based on their exact machinery type, production requirements, and industry standards.

Home

Home Products

Products About Us

About Us Contact Us

Contact Us